- Stage of development

-

TRL4 for CO2. TRL6-7 for agro-industrial waste. Under constant development to further improve the performance of the strain.

- Intellectual property

-

International PCT application filed

- Intended collaboration

-

Licensing and/or co-development

- Contact

-

Victoria MacíasVice-presidency for Innovation and Transfercomercializacion@csic.es

- Reference

-

CSIC/VM/001

Additional information

#Biotechnology

#Biomaterial

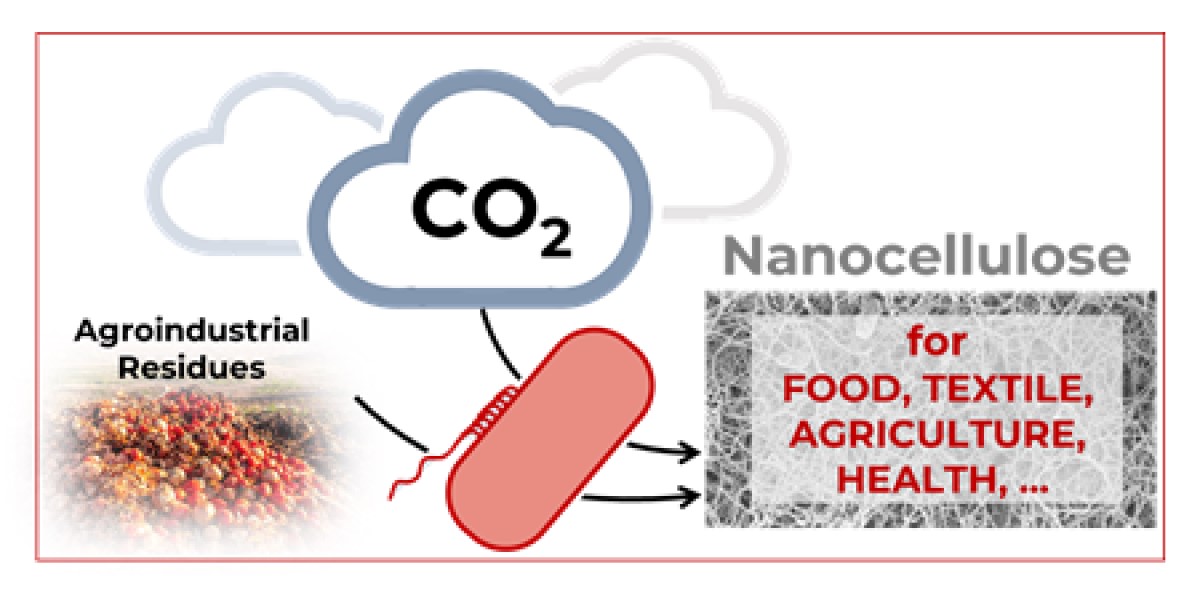

Production of bacterial nanocellulose fromm CO2 or agro-industrial wastes

New bacterial strain with a high capacity to capture CO2 and transform it into added-value nanocellulose. In addition, it produces nanocellulose from different types of agro-industrial waste, including crude glycerin residue from biodiesel production, sugar molasses, whey, etc...

- Market need

-

Industrial activity needs to drastically reduce its carbon footprint, for which innovative and sustainable methodologies are required. The industry must also develop waste minimization and recycling strategies.

Bacterial cellulose is a high quality polymer, with a broad range of biotechnological applications (in wound dressings; as stabilizer or thickener in food and cosmetics; for water treatment; in batteries; in 3D printing; for microencapsulation; in textiles; in vegan meat, etc.), being an optimal basis for the development of new bio-materials to replace fossil fuel derivatives. In a market expected to grow by 13% per year to reach €1.5 billion by 2031, it is imperative to reduce production costs.

- Proposed solution

-

Bacterial strain capable of producing nanocellulose from CO2 and hydrogen.

It is also efficient in the production of nanocellulose from agri-food waste, in a scalable and sustainable way.

Nanocellulose with high water retention capacity and thermal resistance, greater crystallinity and polymerization degree than cellulose of vegetable origin. Applicable to obtain different materials. Environmentally friendly.

Contributes to the reduction of the carbon footprint and sustainability at reduced costs, and to a greener economy by recycling agri-food waste.

- Competitive advantages

-

- Unique capability to transform CO2 into quality nanocellulose.

- Scalable biotechnology for the transformation of agri-food waste into quality nanocellulose.

- High quality nanocellulose, with emphasys on its high water retention capacity and thermal resistance.

- Sustainable and patented production of bacterial nanocellulose.