- Stage of development

-

Technology ready for test in an industrial environment

- Intellectual property

-

PCT application filed

- Intended collaboration

-

Licensing and/or co-development

- Contact

-

Patricia ThomasVice-presidency for Innovation and Transferpatricia.thomas@csic.escomercializacion@csic.es

- Reference

-

CSIC/PT/064

Additional information

#Materials

#Sustainable material

#Waste management

#Nuclear energy

Sustainable cement for nuclear waste management

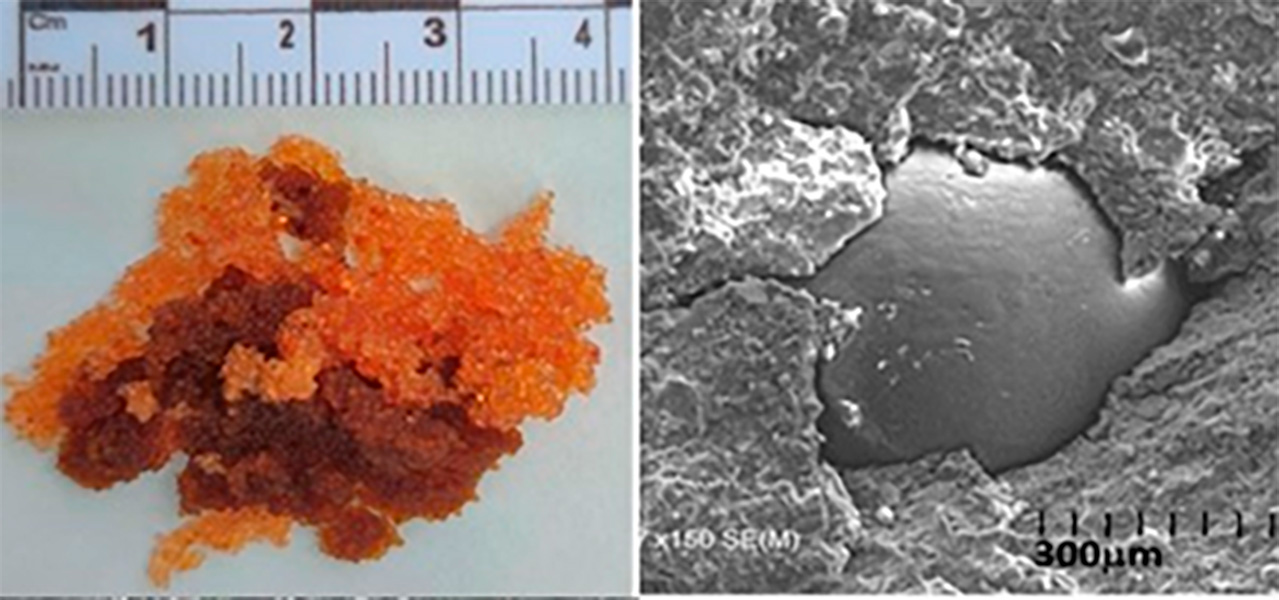

Alkali-activated cement with a low carbon footprint as sustainable alternative to Portland cement for the immobilization of low and intermediate level radioactive waste. It could also be implemented for the management of toxic and/or hazardous waste.

- Market need

-

Spent nuclear grade ion exchange resins are a low and intermediate nuclear waste that entails problems associated with their handling and adequate treatment and which represent the greatest contribution in terms of volume and radiological inventory to wastes of this category in Spain. For these reasons, their management is of great importance. These resins are currently managed by their immobilization in Portland cement-based matrices. Regarding to environmental impact, Portland cement is costly in terms of energy, carbon footprint and mining resources, so alternative solutions are needed.

- Proposed solution

-

The advanced formulations replace Portland cement by blast furnace slag, an industrial by-product. This achieves significant benefits in terms of energy demand, carbon footprint, and mining resource consumption. The use of sodium carbonate and sodium silicate-activated slag cements also allows to safely increase the proportion of ion exchange resin in the conditioning system, thus reducing both the volume and the costs associated with its management. These formulations have also shown good performance in the immobilization of nuclear decontamination sludge.

- Competitive advantages

-

- Alkali-activated slag cement exhibits better mechanical performance, lower porosity, and lower oxygen permeability in the presence of immobilised nuclear waste than traditional Portland-based formulations.

- They show good chemical stability with lower strontium leaching rates.

- A by-product is used as raw material enabling a circular economy model.

- A reduction of up to 90% in CO2 emissions can be achieved since there is no need to use fossil fuels to raise the temperature of the process.